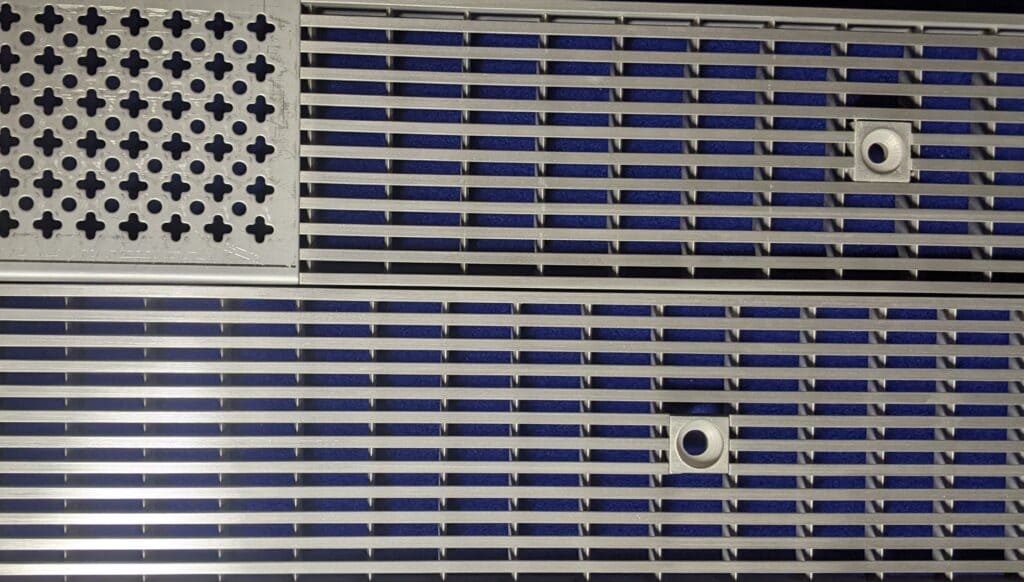

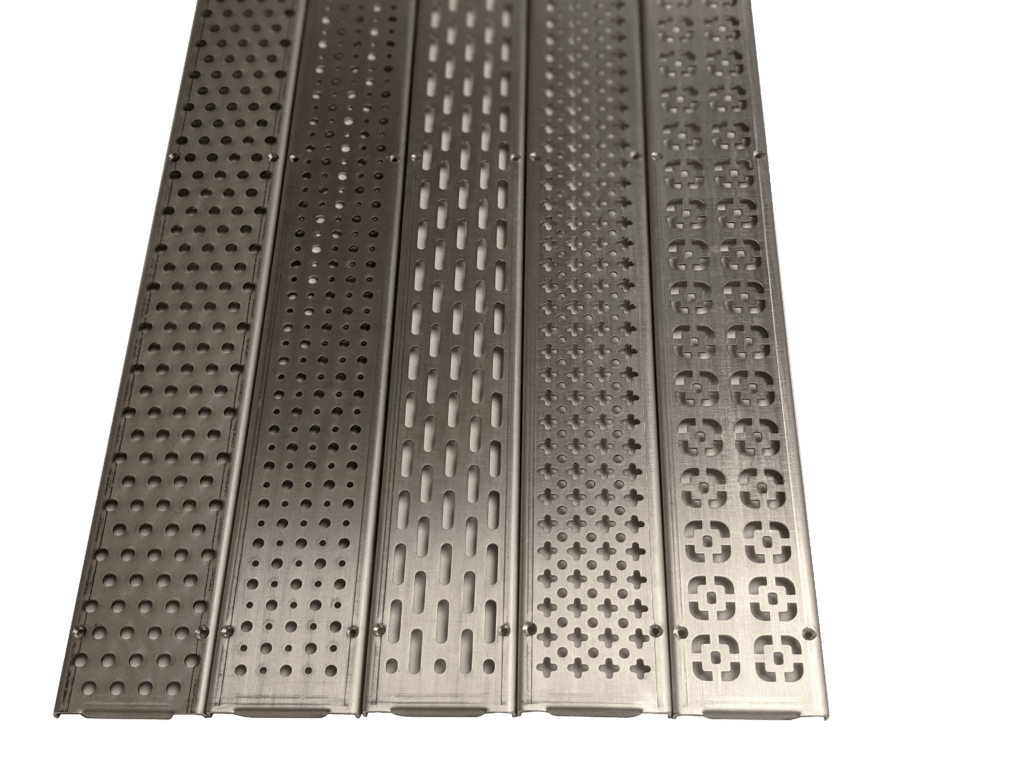

There’s more to a drainage grate than meets the eye. Choosing the right type of material can significantly impact its longevity, durability, and, of course, appearance. Let’s explore two popular types used in manufacturing drainage grates – 304 and 316L stainless steel.

Stainless Steel 304: The Popular Choice

One of the most commonly used materials in drainage grates is 304 stainless steel. This material boasts impressive durability and corrosion resistance due to its high nickel and chromium content. Its robust structure and good forming and welding characteristics make it a popular choice for various applications, including drainage systems.

However, despite its name, “stainless” does not mean it won’t ever stain. Environmental factors, like exposure to salt water or harsh chemicals, can lead to the development of rust on 304 stainless steel grates.

A 304 stainless steel sink showing signs of rust. It can easily be cleaned with Comet or Bar Keeper’s Friend.

Stainless Steel 316L: Superior Corrosion Resistance

Enter the 316L stainless steel, often regarded as a higher grade than its 304 counterpart. 316L is equipped with an added element, molybdenum, which gives it superior corrosion resistance. This extra protection makes 316L a preferred choice for coastal or chemical-heavy environments where salt and other corrosive substances are common.

Galvanized Steel: An Alternative

Besides stainless steel, galvanized steel is another material often employed in drainage grates. It’s a cost-effective option that provides decent protection against corrosion, thanks to a zinc coating that acts as a protective layer. However, if this layer gets scratched or damaged, rusting can occur.

Galvanized grates that are 15 years old positioned in the middle of a residential garage.

Rust Prevention is Key

Whether you opt for a 304, 316L stainless steel, or galvanized steel drainage grate, the common denominator is that they all can rust under certain conditions. The key to maintaining the longevity and performance of your grates is regular cleaning and maintenance. In particular, keep an eye out for any scratches or damages that could expose the base metal to the elements, leading to rusting.

Choosing between 304 and 316L stainless steel or galvanized steel for your drainage grates requires careful consideration of your environment and budget. Understanding the unique characteristics of each material can help you make an informed decision, ensuring your grates stay rust-free for as long as possible.

The experts at TDS can help you find the right drains to fit your plan and budget. Contact us for a free quote or for further information on drainage solutions visit TrenchDrain.com or DrainageKits.com.

Phone: 610-882-3630

Email: Shop@TrenchDrain.com